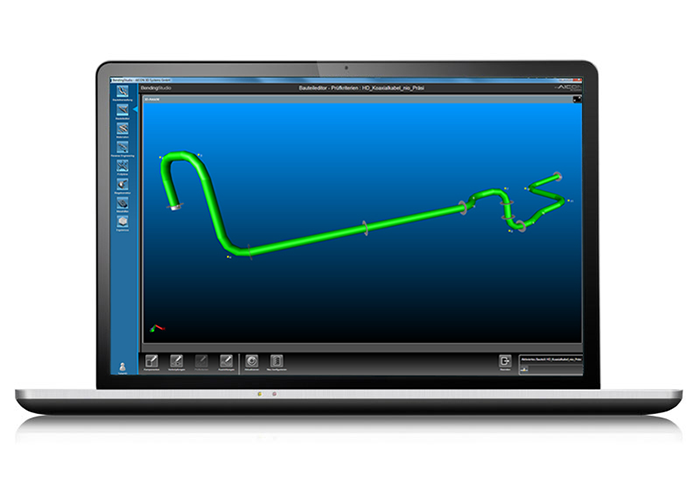

BendingStudio links all data and processes involved in the manufacture of bended parts, from production and process planning to manufacturing and quality control.

It is the only tool to meet and combine these requirements with an emphasis on metrological processes. In combination with TubeInspect or Absolute Arm systems, BendingStudio offers efficient and customer-oriented solutions with a unique combination of speed, accuracy and flexibility.

BendingStudio-CAD-AdaptorFor any part, different data is often required for the different stages on the way from the drawing to the tested product. This includes CAD data from design and bend programs and corrections for manufacturing, as well as test and inspection plans or measurement reports and analysis for quality control. But these records are not always 100 percent compatible.

BendingStudio is focused on bringing together all parallel data sets belonging to any particular part, allowing manufacturers to monitor, quantify, visualise and document all changes throughout the different process steps.

The platform is based on a simple and clearly structured handling concept featuring a variety of small tools to ease daily work in all areas of bended part manufacturing.

The complete platform for bending data and processes

End-to-end management

The BendingStudio platform is designed to offer full communication and data handling across production, quality control and design offices, covering the entire bending production process.

Cross compatibility

BendingStudio allows for complete cross-compatibility between measurement input from TubeInspect and Absolute Arm systems, allowing input from either device to be easily used within the same production structure.

Simple handling

Built on a clear and intuitive structure, BendingStudio allows for easy to understand handling on production data, including one-click functionality for measurement results and data import and export.

Comprehensive interfaces

BendingStudio is built to plug-and-play with the third-party products vital to bending production and control, and includes an open tube bender interface as well as to important statistical process control software such as qs-STAT.

Measurement functions

Bending points, bend data, sheath deviation, deflection compensation and diameter changes are simply handled with BendinStudio, as well as measurement of complex tube structures such as branched tubes and bevel-cut ends.

Measurement jobs

Improve process reliability and enjoy optimisation for series part inspection applications with the implementation of measurement jobs.

Inspection flexibility

Different inspection plans can be assigned to a single part within BendStudio, allowing for the display of drawing requirements and mounting conditions from the same measurement.

CAD-Adaptors

DHigh-definition input systems such as TubeInspect HRC models or the Absolute Arm with RS6 Laser Scanner support CAD-Adpator functionality, allowing for the position and orientation measurement of end holders, fittings and fixtures without mechanical adaptors.